Volume 27.1 |

||||||||||||

| DatapointLabs Is Moving, Looks to Future Expansion | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||

| DatapointLabs Partner Showcase: Altair | ||||||||||||

|

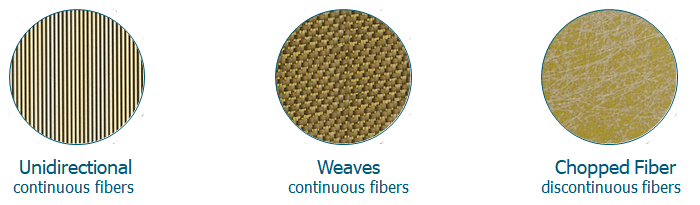

DatapointLabs/Altair Partnership for Accurate and Efficient Simulation of Composites DatapointLabs and Altair have recently partnered to support accurate and efficient simulation of composite materials for CAE product development. Together, we provide CAE material files that are directly informed by DatapointLabs’ precise materials testing and characterization for use with Altair Multiscale Designer®, Altair’s flagship software tool for the simulation of composite materials.

These TestPaks offer timely, precise and relevant material data that is characterized and formatted for seamless CAE simulation input, and include:

TestPaks for Altair Multiscale Designer include both required testing for composite mechanical properties, as well as optional add-in testing for composite physical properties, and matrix mechanical and physical properties. Stochastic characterization – under CMH-17 B18 or similar standard – may also be included. Further, multiple environmental test conditions are available: room temperature dry (RTD), cold temperature dry (CTD), and elevated temperature wet (ETW). Testing may be carried out at static, quasi-static, or dynamic strain rates, as preferred. Measured physical material properties from raw stress-strain curves and DIC measurements are then post-processed into Altair Multiscale Designer material models for subsequent CAE simulation. Harness the combined expertise of both DatapointLabs and Altair in your CAE composite product development. Advanced Crash Material Testing and Models for Altair RADIOSS DatapointLabs offers TestPaks for Altair RADIOSS and has added testing and fitting to support the /FAIL/TAB1 and /FAIL/BiQuad failure models (see the datasheet). In addition, DatapointLabs is contributing to Altair’s newly launched Material Data Center. Example data from DatapointLabs will be available on the Material Data Center from April 2021 onward, to support CAE users in their decision for materials testing. |

||||||||||||

|

||||||||||||