| Upcoming Events | |||||||

|

DatapointLabs Technical Center for Materials is participating in a number of conferences in the coming months, both as event sponsors and technical program participants. The technical papers continue to focus on the topic of “Validate Before You Simulate,” evaluating factors that can affect simulation accuracy. Look for us if you'll be attending one of these events, or contact us to set up an appointment to meet with one of our representatives on site.

|

|||||||

| Technical Publications | |||||||

|

New Book: Determination and Use of Material Properties for Finite Element Analysis DatapointLabs founder and CEO, Hubert Lobo, and laboratory director, Brian Croop, have written a book describing the state of the art in material testing for CAE, which is now available from NAFEMS, the International Association for the Engineering Modelling, Analysis and Simulation Community. This book informs simulation users of the manner and methodologies by which materials are tested in order to calibrate material models currently implemented in various FEA programs. It incorporates extensions beyond basic material models to address currently active areas, including explicit simulation. Find a review of this book on Knowmats.com, a curated repository of information related to materials and simulation. Available directly from NAFEMS.org If you missed our presentations at recent technical conferences, find them at any time on Knowmats.com:

|

|||||||

| DatapointLabs to Offer TestPaks® for GISSMO | |||||||

|

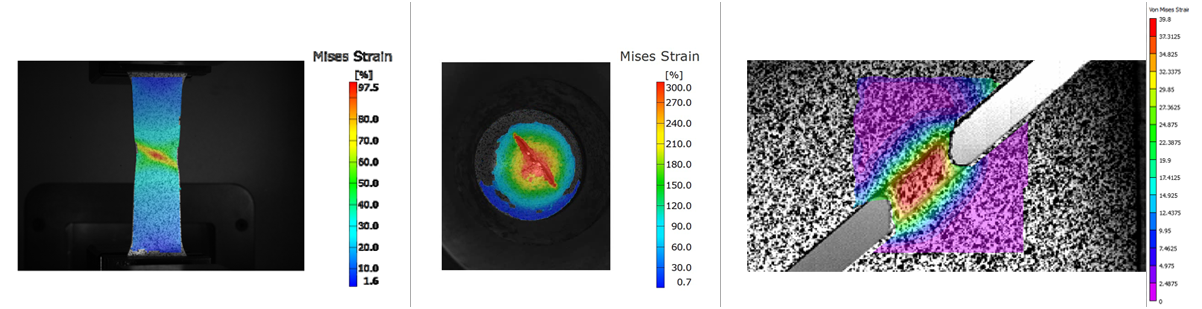

The GISSMO damage model available in *MAT_ADD_EROSION of LS-DYNA provides the ability to add material damage and failure to constitutive material models such as MAT_024, which do not contain this capability. The model is a phenomenological formulation that allows for an incremental description of damage accumulation, including softening and failure for a variety of metallic materials.

TestPaks for GISSMO are provided as a collaboration between DatapointLabs and Dr. Paul Du Bois and include all the specimen preparations, tests, and post-processing of data. An LS-DYNA GISSMO material file is provided. Order the LS-DYNA GISSMO Failure Model TestPak from our online Test Catalog. |

|||||||

| Simulation-driven Product Development Workflows Must Account for Materials | |||||||

|

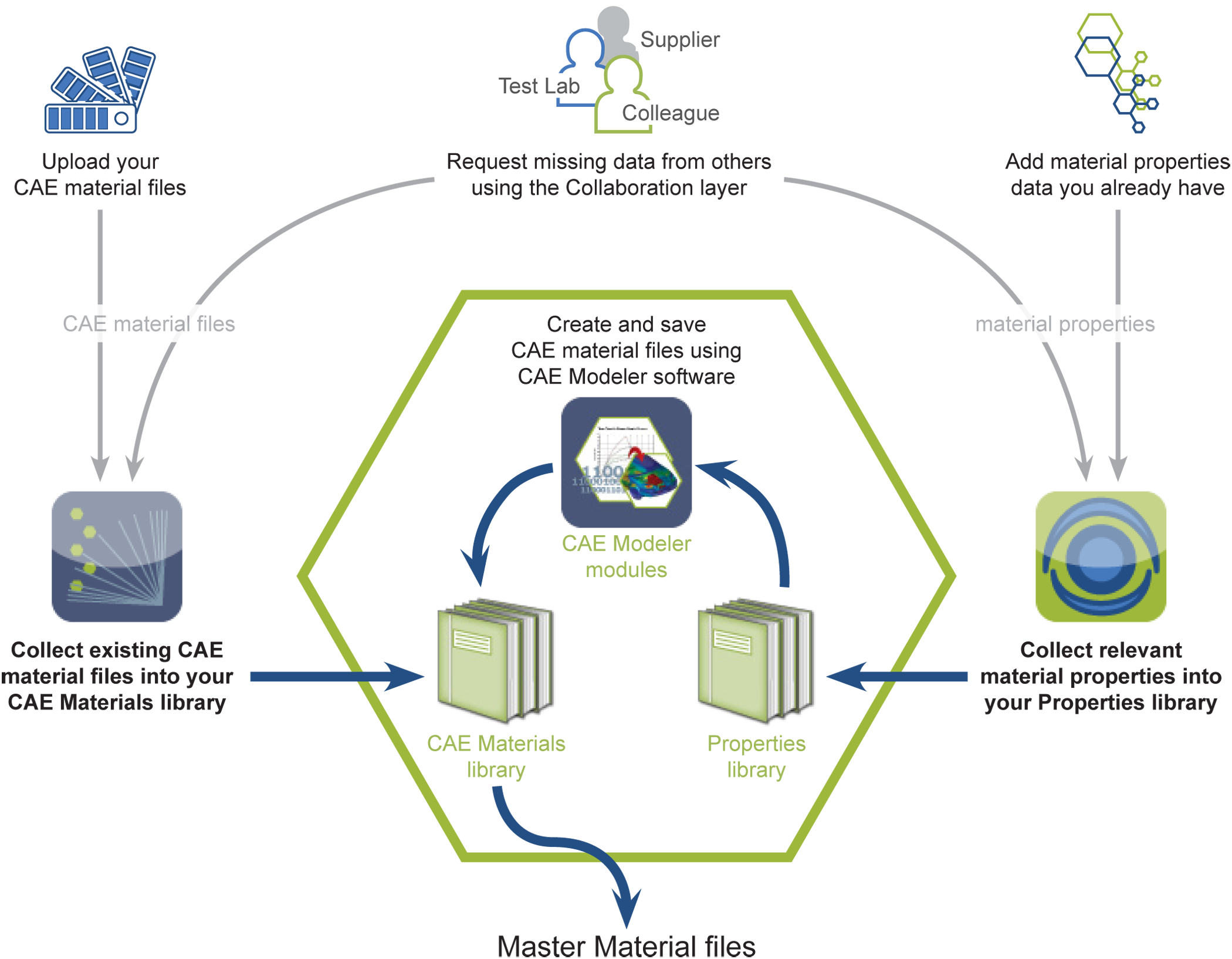

Today’s product development encompasses new materials whose behavior may not yet be completely understood, as well as new and evolving production processes which themselves can affect product performance. The use of simulation has become mainstream, with proof of design and digital prototyping leading to fewer and later-stage physical prototypes being required. In this environment, failure can be expensive. A systematic workflow aims to reduce materials risk through testing, modeling, validation, management, and knowledge capture:

With accurate material properties data, as well as properly evaluated and well fit material models, the objective of achieving an accurate simulation becomes much more feasible. The materials experts at DatapointLabs Technical Center for Materials have been serving material inputs for leading CAE solvers for over two decades. We now offer a range of services and software that facilitate all interactions with materials information across the product life cycle.

Find out more about how the latest release of Matereality® Software for Materials supports an enterprise materials workflow for simulation-driven product development. |

|

||||||

|

strengthening the materials core of manufacturing enterprises |

||||||

|

DatapointLabs, LLC | 95 Brown Road #102, Ithaca, NY 14850 USA | Toll-free: +1-888-DATA-4-CAE | Tel: +1-607-266-0405 | EU, tel: +353 1 442 9204 | info@datapointlabs.com |

|||||||