|

Volume 25.2 |

||||

| Expanded Testing of Metals in Cooperation with other Applus+ Labs | ||||

|

Metals require a range of unique property measurements. While their properties do not vary much in many service environments, creep behavior becomes significant at elevated temperatures, and even the basic stress-strain characteristics are much changed, so that real property measurements are necessary for good design. In addition to stress-strain behavior, cyclic properties including strain-controlled (E-N) and stress-controlled (S-N) fatigue become important. A number of factors come into play here, including strain (stress) ratios, frequency, and temperature, which have a measurable effect on metal behavior and can influence the design of metallic components. DatapointLabs has been increasing its testing capabilities in the area of high strain-rate properties for crash applications, with further new capabilities announced in support of forming simulation and failure modeling of metals. Working in cooperation with other Applus+ labs, DatapointLabs has added a collection of new tests to our TestCart online order system. The new tests address the metals testing needs of our client base with "one-stop shopping" convenience. Applus labs are ISO 17025 certified, and also NADCAP certified where relevant. These new tests are available now:

|

|

|||

| Advancements in the Testing of Biaxial and FLC Properties | ||||

|

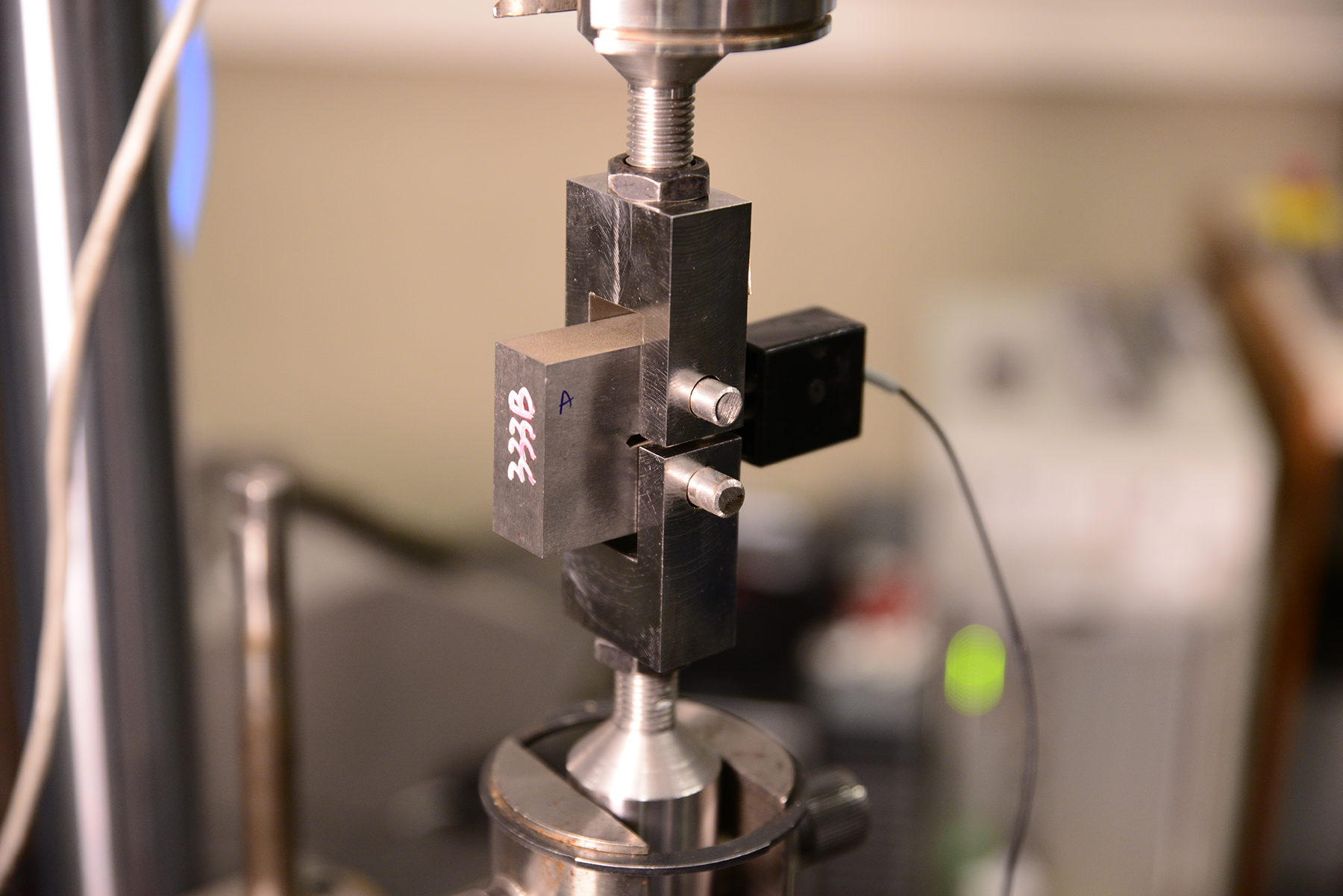

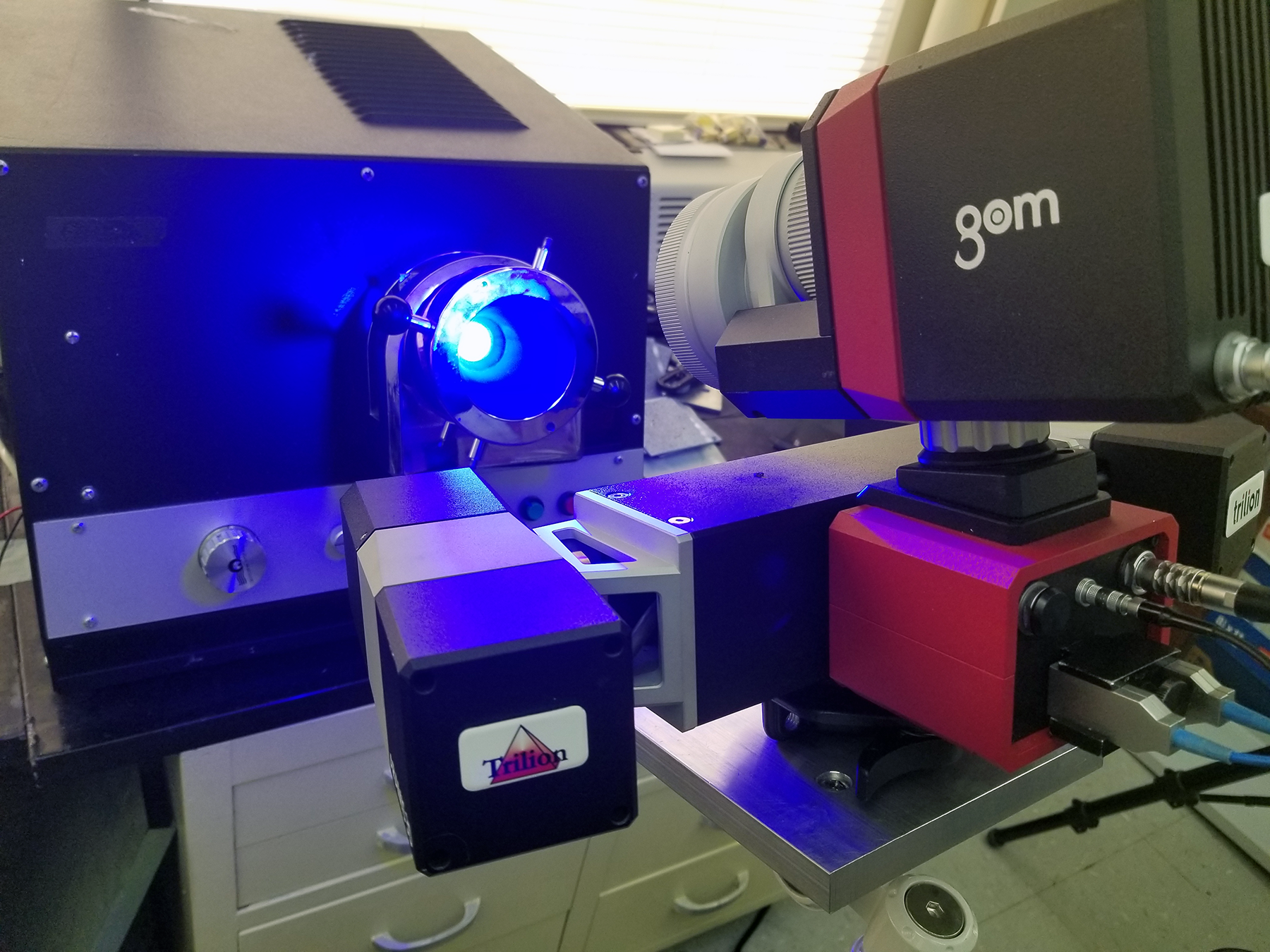

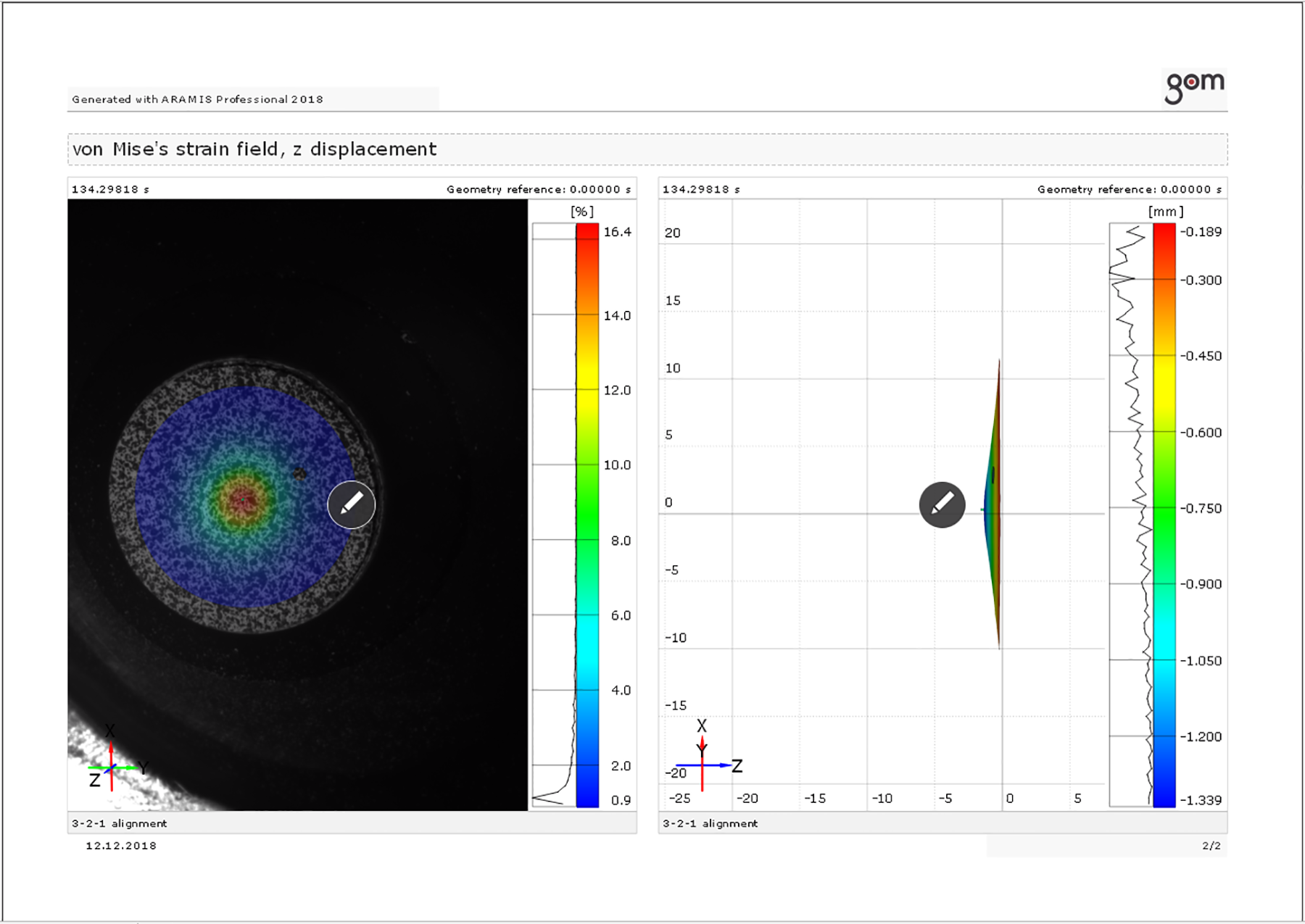

DatapointLabs' updated Erichsen cupping tester used for forming limit curve (FLC) work now includes force and 3D strain measurements: a sheet sample is clamped into the punch testing machine and a hemispherical punch is slowly forced through the sample. The force and the Von Mises surface strains are recorded by way of a pressure transducer and digital image correlation with the ARAMIS 3D DIC camera.

|

||||

| TestPak for Altair Multiscale Designer Software Supports Simulation of Composites | ||||

|

DatapointLabs now offers G-190 Altair Multiscale Designer for Unidirectional (UD) Composites. Data in the form of stress-strain curves paired with DIC images is converted into an Altair Multiscale Designer material model. This material model can be used in structural simulations within a variety of commercial finite element solvers, including Altair OptiStruct, Altair Radioss, Abaqus, and LS-Dyna, to more accurately simulate composite material behavior. More details of the material model and validation studies can be found at Knowmats: A Framework for the Calibration and Validation of Multiscale Material Models. |

||||

| Upcoming Events | ||||

|

DatapointLabs Technical Center for Materials will be participating at the following technical conferences. Look for us if you are attending, or contact us to set up an appointment to meet with one of our representatives there.

|

||||

|

|

||||

| strengthening the materials core of manufacturing enterprises |

||||

|

DatapointLabs Technical Center for Materials | 95 Brown Road #102, Ithaca, NY 14850 USA |

||||